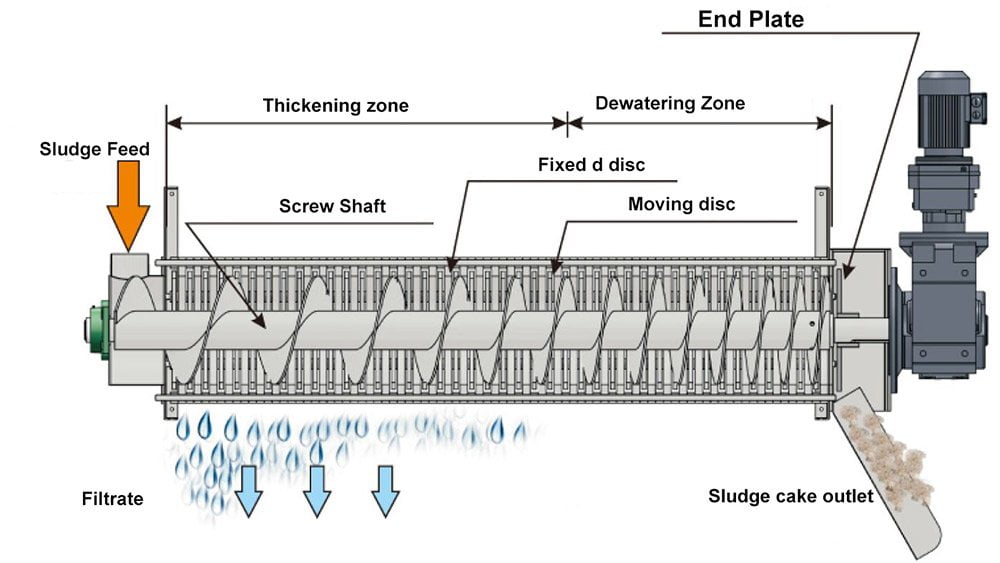

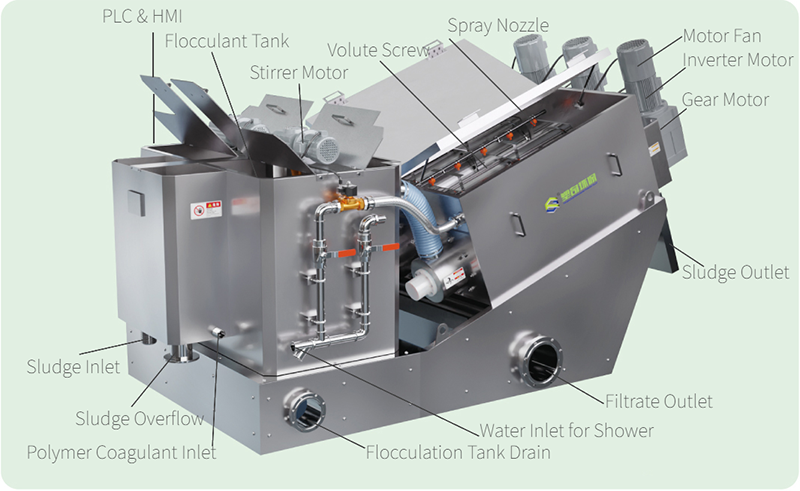

Dual Volute screw press is a screw press that separates liquids from solids. A screw press can be used in place of a belt press, centrifuge, or filter paper. It is a simple, slow moving device that accomplishes dewatering by continuous gravitational drainage.

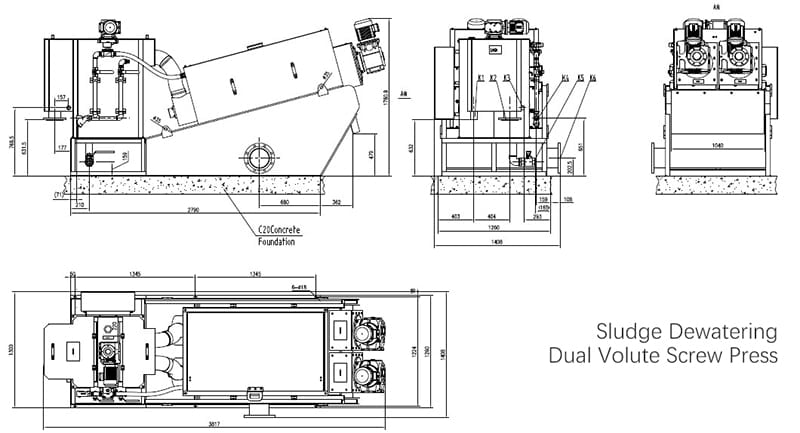

| Model | SQDL132, SQDL252, SQDL302, SQDL352, SQDL402 |

|---|---|

| Power | 0.54KW, 1.47KW, 2.05KW, 2.95KW, 4.50KW |

| Capacity | 100-240KG/H, 12-24KG/H, 30-70KG/H, 60-140KG/H, 80-180KG/H |

| Weight | 1340KG, 1950KG, 2050KG, 350KG, 800KG |